Industrial measurement : technology for automation

To optimise automation processes in a sustainable way, at first their weak points must be detected: A challenge for modern measurement technology :

- Increasing the machine load factor,

- Reducing defective goods,

- Reliable tolerance measurement,

- 100% quality control,

- Preventive error and wear detection

These are just some of the optimizations that can be achieved with ADDI-DATA’s high-precision intelligent measurement systems!

Numerous application fields

Modern measurement technology can be used for various tasks, as many signal types can be acquired. Thus it is possible to identify the different weakness in the automation chain. Here are some examples:

Temperature measurement

- Temperature monitoring in a steelwork

- Temperature regulation for the production of wafers

- Temperature measurement in motor test benches

- Long-term temperature measurement in wind power plants

Pressure measurement

- Boost pressure measurement in motor test benches

- Pressure decrease measurement in a coal-burning power plant

- Force measurement in ABS test benches

- Pressure monitoring in an ethanol factory

Analog signal acquisition

- Press depth monitoring

- Pressure and ultrasound acquisition during flight tests

- Motor current monitoring of a machine tool

- Humidity acquisition of a calibration room

Position acquisition

- Motor rotation acquisition

- Magnet positioning for magnetic resonance imaging

- Pedal travel detection in ABS test benches

- Highly precise acquisition of clock parts

Lenght measurement

- Thickness measurement of flake boards

- Surface corrugation measurement of ceramic balls

- Length and diameter measurement of a spherical roll

- Diameter measurement of gear wheels

Vibration measurement

- Active shock absorption

- Vibration measurement of slowly rotating machines

- Vibration monitoring of large bore engines

- Condition monitoring of bearings and gear drives

Increase productivity

With high-precision DAQ cards and distributed systems by ADDI-DATA you can acquire and process numerous signal types, control and readjust processes directly and loop signals for readjustments and regulation to control units via standard interfaces. The acquired data can also be transferred to super-ordinate databases and software for evaluation and visualisation.

USE CASE

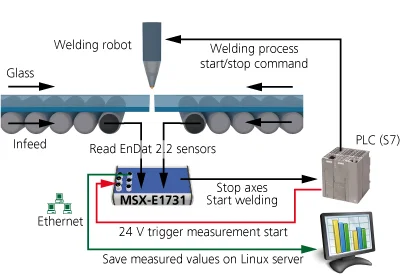

Position acquisition of glass components at a welding process

Challenge:

At the construction of glass components two parts are welded with hot air. As the material is very fragile the welding process must be carried out very carefully and precisely (1 µm) despite of the speed in order to avoid the breaking of the parts.

Furthermore it must be made sure that the glass components are close enough to guarantee a good quality of the weld seam. Thus the components’ position shall be acquired in intervals of 200 ms.

Solution:

For the position detection of the glass components the Ethernet counter system MSX-E1731 via EnDat 2.2 sensors has been chosen due to its speed and precision.

At the beginning of the welding process the SPS triggers the MSXE1731 system to start the measurement process. As soon as the glass components are in the correct position the system sends two signals: One for the digital output to stop the axes and via Ethernet the start signal for the welding process. When the welding phase is over all acquired data is transferred to a Linux server for archival storage.

ADDI-DATA SOLUTION

DAQ cards

• For various signal types

• High precision

• Robust and interference-resistant

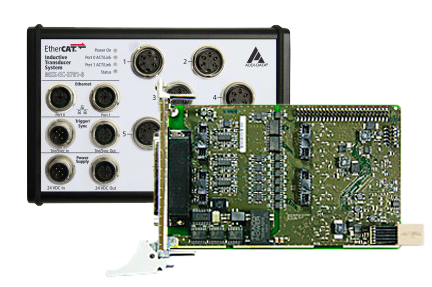

Real-time systems

• EtherCAT and Profinet

• Linux systems including real-time extension

• PC boards with RTX real-time drivers

Ethernet systems

• Direct sensor connection

• Onboard calculation of the acquired data

• For use in the field, up to IP 67

Data loggers

• Long-term data acquisition of numerous signal types

• Setup of the measurement device without programming knowledge

• Visualisation of the live data

Customized solutions

The best solution often is customized. As a manufacturer, we are able to adapt our solutions as closely as possible to your requirements. We are pleased to advise you on finding the best solution for your applications and to perform the necessary adaptations for you.

Just ask us!